Application programming

Application programming

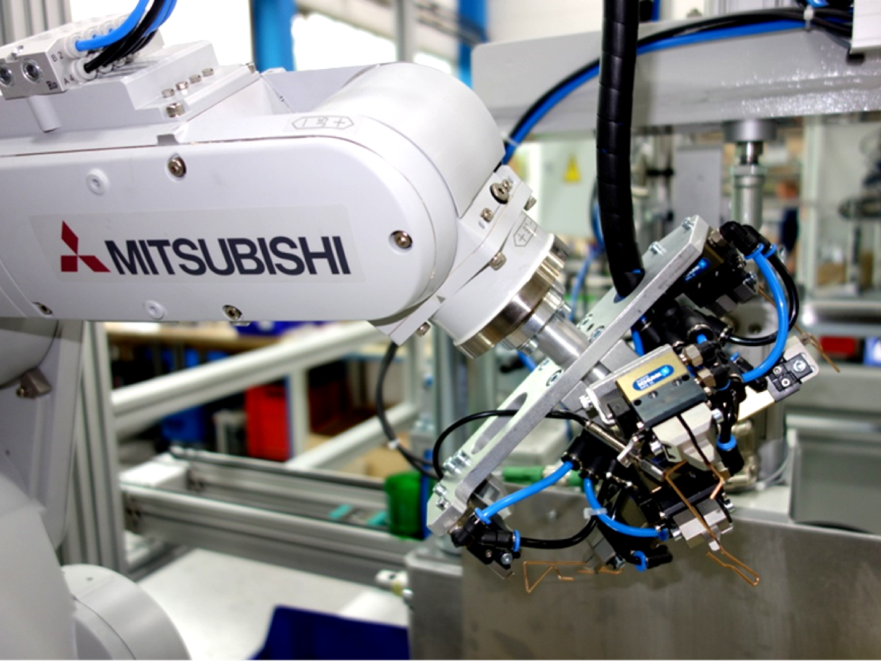

We offer manufacturer-independent robot programming with over 30 years of experience in industrial applications. Our focus is on the programming and integration of robots.

Our technical expertise covers the entire chain from concept development to cycle time optimization - tailored to real production conditions, external systems and higher-level control systems.

Range of services

- Robot programming (online/offline):

Cross-manufacturer programming of robots from Mitsubishi, ABB, FANUC, Yaskawa, Stäubli and UR, among others - Integration of complex applications:

Broad expertise in tasks such as pick-and-place, palletizing, welding, gluing, measuring, deburring, testing, packaging - in each case taking into account external sensors and actuators. - 3D bin picking / camera-guided applications:

Implementation of "bin picking" scenarios with connection of 2D and 3D vision systems (e.g. Keyence, SICK, ifm, Cognex) including calibration and real-time data transfer. - Control of additional axes:

Integration of linear units, rotary axes, gantries and axis combinations directly via the robot controller (external kinematics models, synchronized motion planning). - Conveyor tracking:

Implementation of conveyor-guided applications with robot-side position tracking - synchronized with a clock or continuously running conveyor belt. - PLC robot interfaces:

Implementation of robust, standardized communication interfaces (Profinet, EtherCAT, EtherNet/IP, OPC UA) to the higher-level controller including cycle transfer, status feedback and diagnostic interface. - Creation of operator interfaces:

Implementation of visualizations on HMI - with remote access (remote maintenance) on request. - Automation of machine tools:

Robot connection to CNC and machining centers via standardized handshake protocols, NC interfaces or I/O communication. - Real-time applications:

Implementation of synchronized motion sequences in applications with strict reaction times - e.g. for press interlinking, testing processes or multi-axis transfer systems. - Simulation & offline validation:

Use of simulation tools to validate complex motion sequences and reachability at an early stage. - Cycle time optimization:

Systematic analysis and optimization of motion profiles, TCP paths, blending parameters, subroutine logic and communication behaviour.