Robot systems

We have experience with:

- Mitsubishi

- KUKA

- ABB

- Yaskawa

- Fanuc

- Stäubli

- Universal Robot

- Denso

- Simulation with CIROS

You are interested in:

Robots from Mitsubishi

You are looking for the right Mitsubishi robot for your application.

We will be happy to advise you...

Exemplary:

Mitsubishi RV-2FRB-D: Adiro Fast Facts

→

Cartesian robots

With motion controllers from Festo, Keba or Siemens, our Cartesian robots from Festo can be programmed like any standard industrial robot. Our Cartesian robots combine proven Festo axis systems with powerful drives and an intelligent control architecture - for maximum precision and maximum process reliability in your automation.

Whether for pick-and-place applications, dosing tasks, palletizing or other handling processes - our modular systems can be tailored precisely to your requirements.

Components & features at a glance:

- Drive technology from Festo: High-quality linear units and axes ensure reliable motion sequences in up to three axes (X, Y, Z).

- Flexible control selection: Integration with either Festo, Siemens or Keba control systems - to match your existing infrastructure.

- Drive solutions as required: Choice between different stepper motors and servomotors - individually matched to dynamics, load and accuracy.

- Modern drive controllers: Powerful and easily parameterizable controllers ensure precise motion control.

- Integrated energy management concept: Compact, clear and easy to maintain - for maximum operational reliability and a tidy machine design

Your benefits at a glance:

- High repeat accuracy and travel speed

- Scalable system - from compact units to large-format gantries

- Fast integration into existing processes thanks to open interfaces

- Service-friendly design and long component service life

Our Cartesian robot systems are the ideal solution for automation tasks in assembly, packaging, laboratory automation and many other industrial sectors.

Contact us - we will be happy to advise you on the right system for your application!

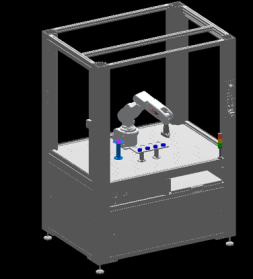

Standard training cell

Do you want to train your personnel outside of production processes? Then use our standard robot training cell in combination with the latest safety technology.

Highlights:

- Force-controlled robot application with ForceSensor (200N)

- Safety:

- Extremely high Pilz safety technology e.g:

- PSENmlock - safety switch with guard locking

- PITgatebox + PITreader: Operating unit with access authorization system for controlling safety gate switches and systems.

- Coupling of the robot controller and the SafetyOp with the safety controller for safe operation of the robot in the emergency stop, safety gate and safety functions SLS and STO safety circuits.

- Learning platform for OPC UA by incorporating various PLCs from Mitsubishi, Siemens and Pilz and an HMI with OPC UA interface

- ROS

- PLC and robot connection: Robot connection to Mitsubishi PLC (via CCLink IE Field Basic) or Siemens S7

- IO-Link multi-segment LED strips

Customized robot cells

We offer robot cells that can be designed to be modular and application-specific. Depending on the intended use and spatial conditions, we realize different cell variants - from fully enclosed cells to mobile trolleys with cobots.

Possible cell variants:

Fully enclosed cell:

Enclosed robot cell with safety enclosure. Suitable for automation tasks with increased protection requirements, for example at higher speeds or greater forces.

Partially open cell with safety technology:

Open design with protection via safety light curtains or laser scanners. This variant enables easier access with standard-compliant personal protection.

Compact cobot station:

Mobile platform for lightweight robots, especially for training or demonstration purposes.

Robot equipment:

- Depending on requirements, we equip the cell with robots from different manufacturers and designs.

Depending on the project, integration takes place with adapted peripherals (grippers, sensors, safety technology) and optionally with a PLC connection.

Further options:

- Electric or pneumatic grippers

- Camera systems (2D/3D) for part recognition

- Manual or automatic gripper changing system

- Control panel with HMI or push-button panel

- CE-compliant safety technology in accordance with the Machinery Directive

We will create an individual cell concept for specific requirements.

Please contact us directly - we will be happy to check feasibility, design and integration together with you.

Gripper adapter plates

Are you looking for the right gripper for your application?

Contact us and we will advise you and manufacture the gripper adapter plate for you, for example.